INDUSTRIAL BISCUIT LINES

CUPCAKE

A cupcake (literally, in English, “cake in a cup”), also called a fairy cake in England and patty cake in Australia, is a sweet mini-cake cooked in a ceramic cup, greased and floured, or in a mold of parchment paper such as that used for making muffins. Cupcakes have been popular in Italy for some years now.

The original recipe includes a glazing, called “frosting” (royal icing, naspro, icing, sugar paste or butter cream), a filling with cream and a decoration in colored sugar or plastic chocolate with the most classic cherry.

EXAMPLE OF CUPCAKE LINE

PLANETARY MIXER

DEPOSITOR

TUNNEL OVEN

COOLING CONVEYOR

DECORATION

HANDLING AND PACKING

MIXERS MANUFACTURED EVERY YEAR

The dough is the first phase of the process and one of the most critical:

great importance is given to the homogeneity of the dough and its characteristics. How the ingredients are dosed, blended and incorporated, producing the correct amount of gluten during mixing and developing the correct temperature is essential to have a constant and machinable product in the subsequent phases. Laser can count on different types of mixers produced internally through years of experience gained in contact with its customers all over the world. More info

feeding solutions: direct feeding, intermediate short rest, long fermentation on bowls

once the dough is created it must be transferred to the DEPOSITOR.

It could be a direct process, with resting period of a few minutes, or require a fermentation of several hours. The mixing room could be near the process area, or on a separate floor. In any case Laser has various technical solutions to automate this phase. Often the dough is also checked to avoid the presence of contaminating materials that could damage the following stations.

AND MORE SOLUTION FOR CUSTOMIZING THE FINAL PRODUCT

Each production line can be customized with various accessories:

to make the cupcake unique or make the same line more flexible and able to respond to market demands. Distribution systems for granulates, wetting and glazing can be easily integrated into the layout of the line to ensure that each product is unique in the market.

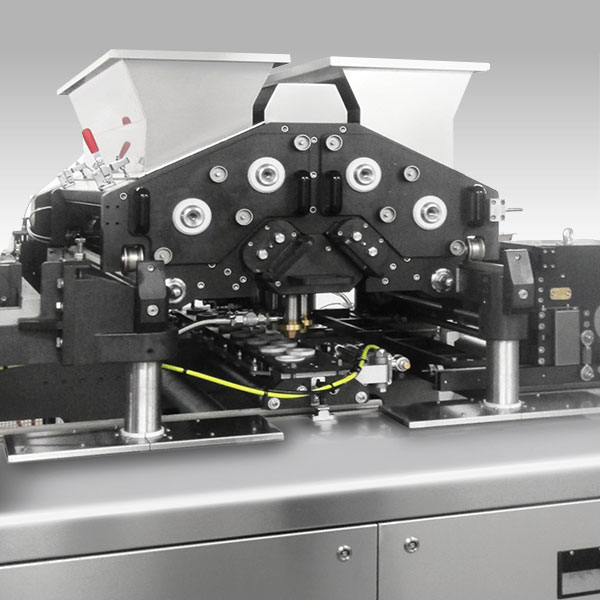

CUPCAKE DEPOSITOR AND INJECTOR

THE DEPOSIT PHASE IS THE HEART OF THE CREATION OF THE BISCUIT.

The precision mechanics combined with a sophisticated control of brushless drives allows to reach high output and an extreme precision on the finished product, all controlled by an intuitive operator panel and with the ability to record many recipes.

LASER BISCUIT LINES

TAKE YOUR PRODUCTION TO THE NEXT LEVEL

Our experience in the sector with over 500 plants commissioned, combined with the high production of machines, allows us to offer a personalized choice of solutions for each customer.

The Laser production program includes complete automatic process lines with a high productivity yield for biscuits, pastry and breads, designed and manufactured with the use of innovative technologies and excellent materials.

DIFFERENT TYPE OF TUNNEL OVEN

The oven is the master of reference for the entire line and determines its production capacity.

Proper baking and correct profiling of the parameters of each zone is the secret to obtain a constant and efficient production. Whether the oven is powered by gas, diesel or electric, which it bakes by radiation or convection, Laser has a solution for every need. Different types of baking and fuel can be combined to give an optimal and at the same time flexible result for

modern industry. More info

The ideal solution for the production of cupcakes is the hybrid oven, consisting of a cyclothermic oven followed by a convection oven.

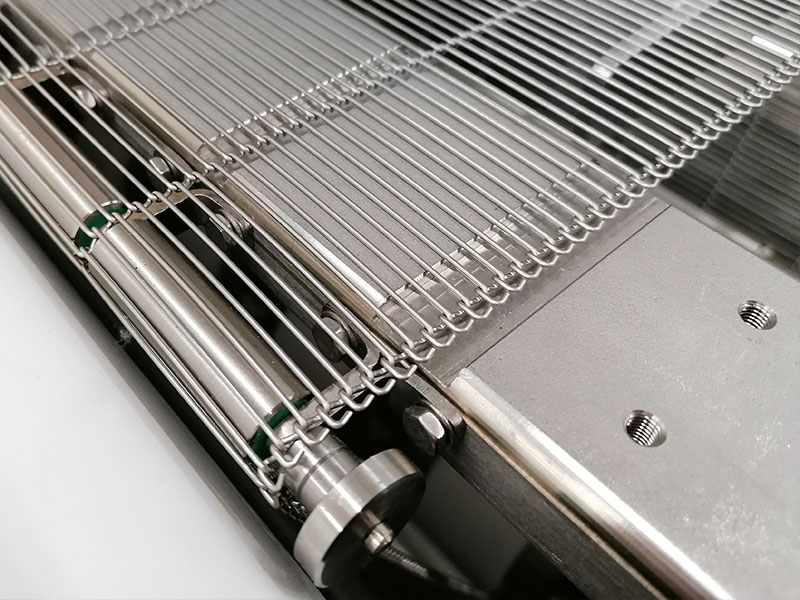

KM OF COOLING CONVEYORS MANUFACTURED EVERY YEAR

Once baking is over, the PRODUCT must be cooled and transported to the packaging “islands”.

Maintaining a constant alignment and non-aggressive cooling are essential for obtaining a whole product that does not break, can be easily stacked and packaged. Nobody wants a package of crumbs! More than 3,500 meters of cooling conveyors are carried out each year, transporting each cookie to stacking stations. Subsequently, the product can be conveyed to the packaging machines automatically or manually depending on the system and the speeds. There could be several packaging “islands”, or several production lines, in this case an integrated system allows a production flexibility necessary for the modern industry.

RECIPES STORED IN OUR SOFTWARE MANAGEMENT SYSTEM

The entire system is managed completely automatically by one or more PLCs.

The software allows to manage the recipe and production parameters and also be connected to the customer’s company networks if necessary. Extensive customization and on-line assistance give the customer a support according to his production needs.

NEXT STEP

TASTE THE QUALITY

STAY IN TOUCH

The Latest News & Updates

About Us

Products

Get involved

LASER S.R.L.

Via Saturno 36

37059 Santa Maria di Zevio

Verona – Italy

Ph. (+39) 045 6051428

contact@laserbiscuit.it

P.IVA 02640680233