Cooling Tunnel

Industrial Tunnel Machine

POST OVEN MACHINES

COOLING TUNNEL

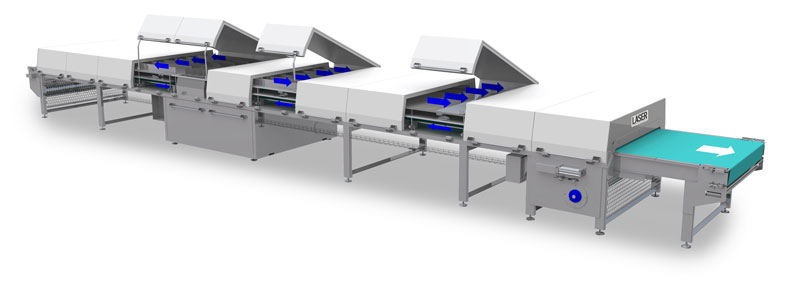

For some products, decorated with chocolate, creams, jams and similar, the cooling conveyors are not enough to cool the product but it is necessary to have a cooling tunnel able to quickly cool the product.

Our industrial cooling tunnels and cooling conveyors are custom-built to meet bakery needs and the equipment is designed using all current industry best practices for cooling various bakery and confectionery products such as cookies, biscuits, molded chocolate, and enrobed confections.

The cooling tunnel is also available in the stainless steel version.

Cooling tunnel: THE indispensable MACHINE for instant cooling

The cooling tunnels are supplied with cooling units of different capacities dependent upon the actual refrigerating output and the length of the tunnel. These cooling units may be located in the midsection of the tunnel, on its outside or even outside the building – as per customer’s requirements.

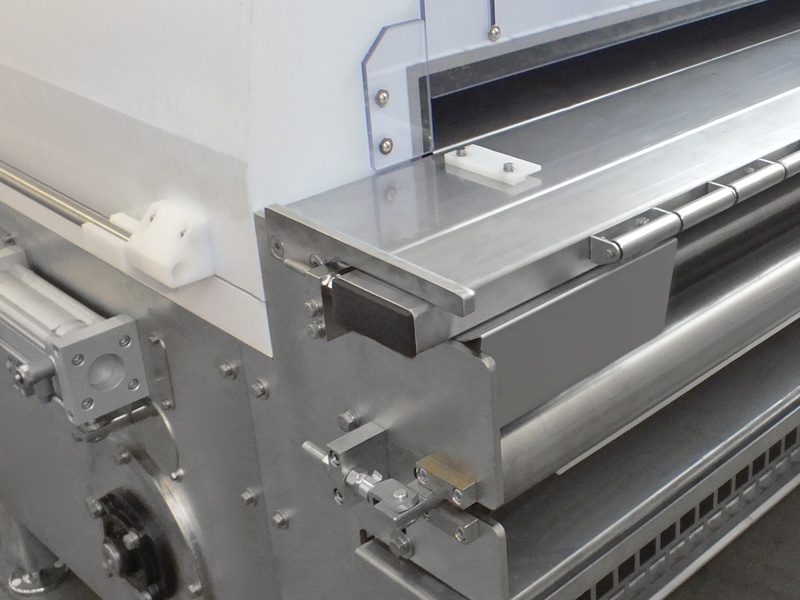

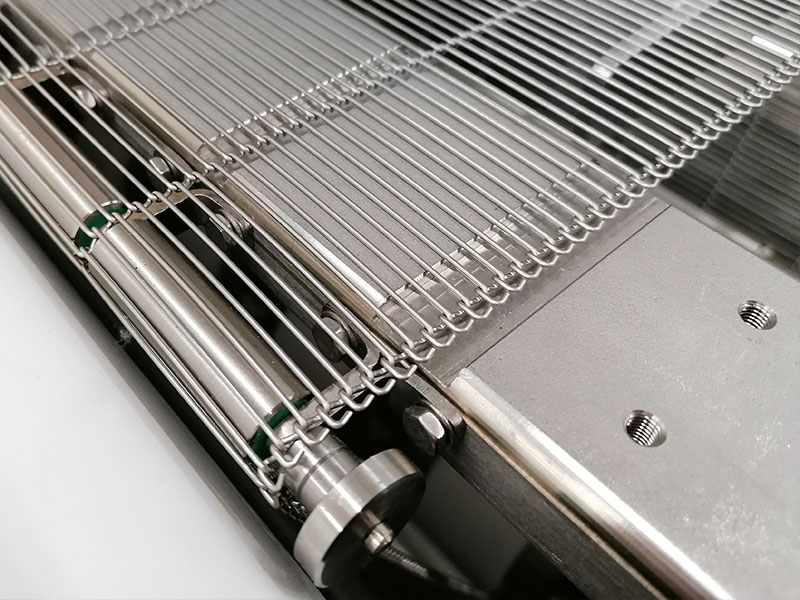

THE COOLING Biscuit Transport System

Conveyor eliminates mist during cooling, and replacing water quench to reduce cool down time. There are several different ways in which cooling conveyors can operate. By the time products have passed through the cooling conveyor, they’re suitable for packaging and shipping.

km of cooling conveyors manufactured every year

Once baking is over, the soft biscuit must be cooled and transported to the packaging “islands”.

Maintaining a constant alignment and non-aggressive cooling are essential for obtaining a whole product that does not break, can be easily stacked and packaged. Nobody wants a package of crumbs! More than 3,500 meters of cooling conveyors are carried out each year, transporting each cookie to stacking stations. Subsequently, the biscuit can be conveyed to the packaging machines automatically or manually depending on the system and the speeds. There could be several packaging “islands”, or several production lines, in this case an integrated system allows a production flexibility necessary for the modern industry.

RECIPES STORED IN OUR SOFTWARE MANAGEMENT SYSTEM

THE ENTIRE SYSTEM IS MANAGED COMPLETELY AUTOMATICALLY BY ONE OR MORE PLCS.

The software allows to manage the recipe and production parameters and also be connected to the customer’s company networks if necessary. Extensive customization and on-line assistance give the customer a support according to his production needs.

LASER BISCUIT LINES

TAKE YOUR PRODUCTION TO THE NEXT LEVEL

Our experience in the sector with over 500 plants commissioned, combined with the high production of machines, allows us to offer a personalized choice of solutions for each customer.

The Laser production program includes complete automatic process lines with a high productivity yield for biscuits, pastry and breads, designed and manufactured with the use of innovative technologies and excellent materials.

STAY IN TOUCH

The Latest News & Updates

About Us

Products

LASER S.R.L.

Via Saturno 36

37059 Santa Maria di Zevio

Verona – Italy

Ph. (+39) 045 6051428

contact@laserbiscuit.it

P.IVA 02640680233