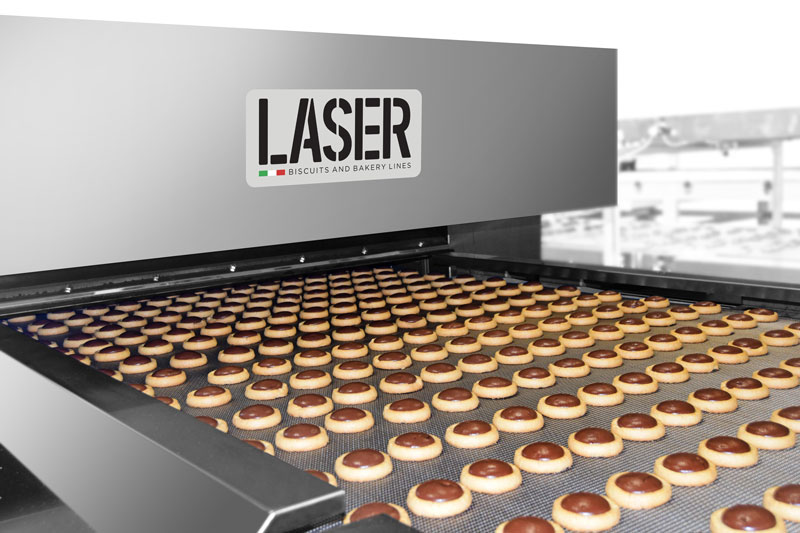

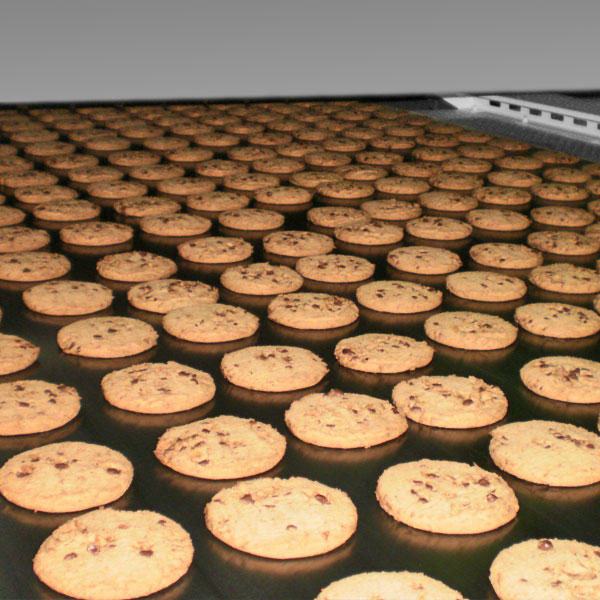

INDUSTRIAL BISCUITS AND BAKERY LINES

TUNNEL OVEN

Laser designs and manifactures tunnel oven for industrial production.

Tunnel ovens use different heating methods, conveyor speeds and fuel types to produce breads, biscuits, and other items.

A wide range of models working with different heating systems.

Their equipment and dimensions can be adapted according to the production needs.

Our technical department is at complete disposal for any kind of information aimed at the supply of a first rate plant granting performances and reliability.

TYPE OF TUNNEL OVEN

TUNNEL OVEN EVERY YEAR

TYPE OF TUNNEL OVEN

MAX LENGTH METERS

MAX WIDTH METERS

CYCLOTHERMIC TUNNEL OVEN

The cyclothermic TUNNEL oven is the most traditional tunnel oven and one of the most used in the world

Inside a room of combustion in steel and refractory combustion develops thanks to a modulating burner that can work gas or diesel. The combustion fumes are conveyed thanks to a fan with two upper tube bundles and lower in order to heat them and cook the product by radiation. the high thermal mass, flexibility of use of different fuels and independent upper and lower heat regulation, combined with humidity control accurate, has made this technology very popular for dry biscuits, shortbread, bread, cakes, cakes and other products. There reduced maintenance and ease of use make it suitable for many situations.

CONVECTION TUNNEL OVEN

The direct or indirect convection TUNNEL oven transmits heat through a flow of hot air that is generated in the furnace top of the area.

This flow of hot air is generated by a modulating gas burner (in the case of the direct convection) or from a heat exchanger where the indirect combustion and heating process takes place cooking air. The heated air is conveyed into the baking chamber through ducts appropriately shaped and blown onto the product. The air is recovered through lateral ducts and then partially expelled and re-integrated with fresh air. Convection cooking favors fatty doughs such as shortbread, extruded products and pastry and is suitable for obtaining low humidity and uniform color on production.

ELECTRIC TUNNEL OVEN

The electric TUNNEL oven is the most environmentally friendly as it does not use fossil fuels

and is the absolute oven with the best temperature control and with the least maintenance required. Several toroidal resistors are installed transversely to the direction of travel of the oven both in the upper and lower part of the conveyor to allow you to cook flexibly. A PLC control system manages the modulation of the baking zones while suction is guaranteed by a central duct that guarantees constant suction with the least possible turbulence.

DIRECT GAS TUNNEL OVEN

The direct flame TUNNEL oven is especially used in the production of crackers and laminates due to its high transfer of heat mainly by radiation.

Numerous ribbon burners are installed transversely to the direction of travel

of the tunnel oven both in the upper and in the lower part of the conveyor to allow baking in a manner flexible according to needs. about 15% of these burners are tri-flame with the possibility of adjusting on the left, in the center and on the right the power and make the cooking of the product uniform over the entire width of the band. Every burner is equipped with a double gas safety valve and a dedicated flame control and can be used natural gas or LPG indiscriminately thanks to a simple recalibration of the mixer of each burner while aspiration it is guaranteed by a central duct that guarantees constant suction with the least possible turbulence.

HYBRID TUNNEL OVEN

The ideal personalized BAking.

For the baking of specific products it is possible to combine the previous ovens and obtain baking that best suits the needs of the individual customer.

CUSTOMIZED SOLUTION OF TUNNEL OVENS

The construction of special high temperature TUNNEL OVENS

for the baking of nachos, tortillas and wraps also multi-level, tunnel ovens for the grilling and baking of vegetables, and more, are part of the product portfolio that Laser can offer.

SUPER SIZE!

Laser is able to produce lines up to 4 meters wide for important productions

To satisfy all types of customers, Laser has adapted to different production widths. The sturdiness of the structure, combined with the care of the materials, offer the tranquility of an absolute quality product even for important productions.

EXTREME CUSTOMIZATION

MANY options and customizations can be integrated into the Laser TUNNEL ovens to facilitate BAking as well as maintenance and cleaning

Cleaning systems for belts or nets, tunnel oven unloading conveyors, automation complete with cooking parameters with pressure sensors are some of the options that you can to install. it is also possible to integrate the oven with steam injection systems, glazing via infrared burners, internal turbulence generation systems, and special designs suitable for particular products can be adopted to further customize the cooking of more complex products.

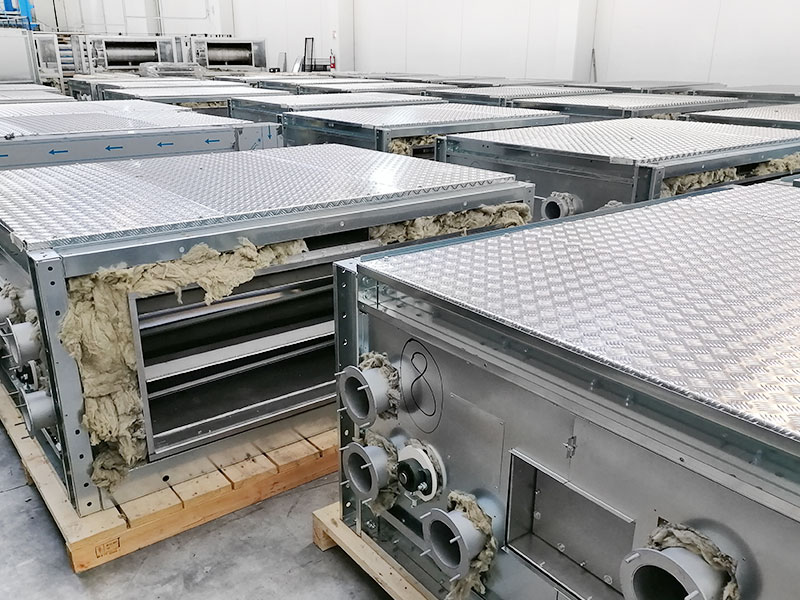

The tranquility of assembly of modular ovens

The assembly phase cannot be neglected

Laser produces modular ovens that can be transported in blocks that can be perfectly assembled at the customer’s company with greater ease, precision and time optimization.

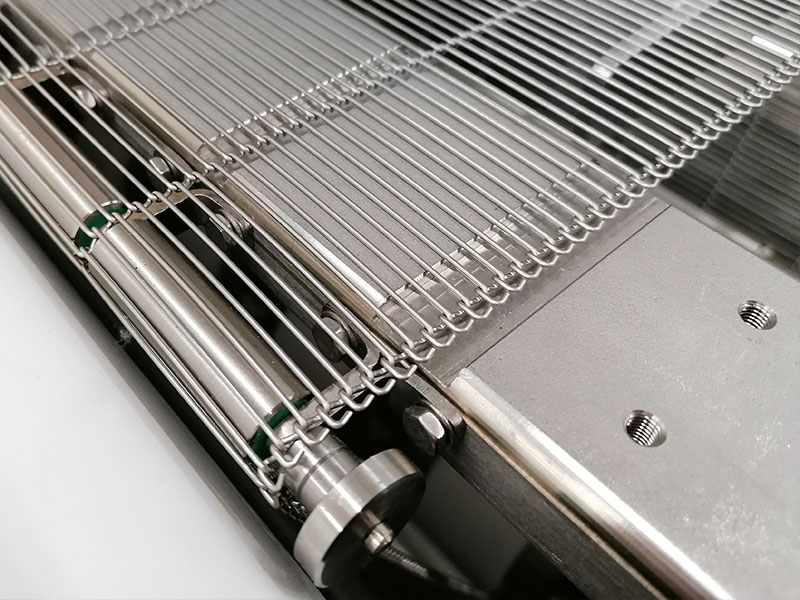

CONVEYORS

Numerous conveyors can be used in laser TUNNEL ovens to support the cooking of the most demanding products.

From IPCO solid or perforated steel bands, to Z47 or CB3 or CB5 type nets, up to dedicated transport for trays or belts in plastic material it is possible to design the correct oven transport system for each product. automatic systems

tensioning and centering systems with intelligent operation, UPS systems for emergency product unloading, cleaning brushes or scraper assemblies ensure that the useful life of the conveyor is maximized and costs are reduced maintenance and cleaning.

NEXT STEP

TASTE THE QUALITY

Ovens, thermocycle oven, cyclothermic oven, convection oven, tunnel oven, electric oven, industrial oven, food oven, oven products, rotary oven, professional oven, biscuit oven, pastries oven, bread oven, bakery oven, oven for bakery, oven for pastry making, machine for bakery, oven assistance, oven overhauling, oven lenght, baking, cooking

STAY IN TOUCH

The Latest News & Updates

About Us

Products

LASER S.R.L.

Via Saturno 36

37059 Santa Maria di Zevio

Verona – Italy

Ph. (+39) 045 6051428

contact@laserbiscuit.it

P.IVA 02640680233