Sandwich machine

Sandwich biscuit with cream distributor

INDUSTRIAL BISCUIT LINES

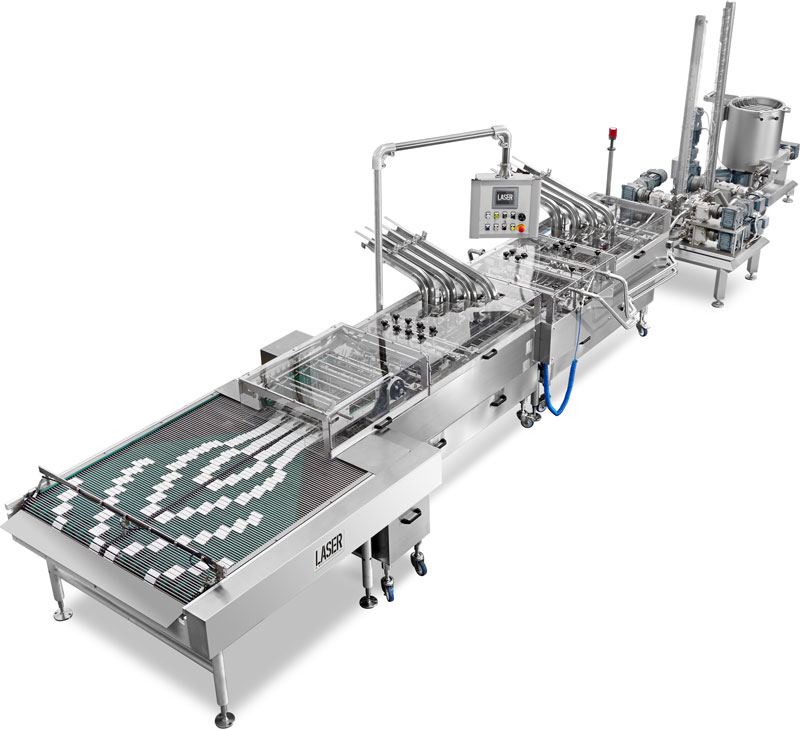

SANDWICH MACHINE

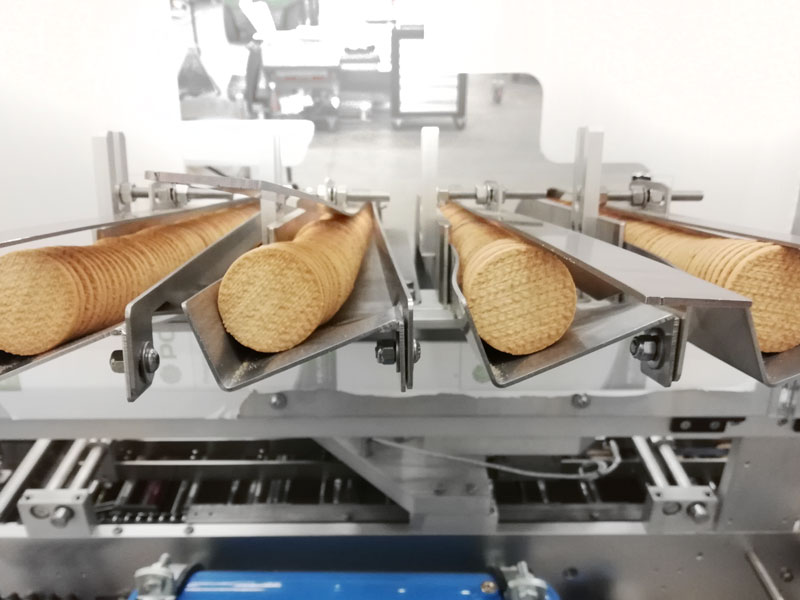

The Biscuit Sandwich filler with cream dispenser (stencil) is capable of producing sandwich products with an extruded and wire-cut cream inserted in the middle. The machine is loaded through vibrating feed channels from which biscuits enter tracks driven by biscuit feed chains. The cream deposit is made thanks to a rotating stencil, fed by a group of cream pumps from which the filling accumulates and is metered into the upper part of the machine body. After distributing the cream, the superposition of a second biscuit completes the sandwich procedure. Finally, a thickness regulator and a photocell detect product compliance.

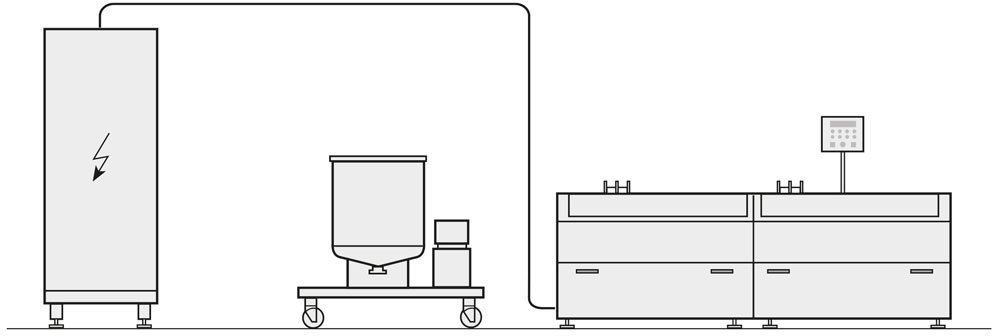

CREAM TANK, AGITATOR AND PUMP GROUP FOR SANDWICH FILLING MILL

● AISI 304 stainless steel tank with jacket, with the agitator at the bottom that takes the cream to the cochlea and then to the feed pump

● Lobe pumps complete with standard rotors each to provide a line

● Connection between cream dispenser (stencil) and pump through 3 meters of double-walled tube in AISI 304 stainless steel

● Cream pressure controller to control cream on each sandwich cookie

● Control of the indexed speed of the motors with the speed of the sandwiches

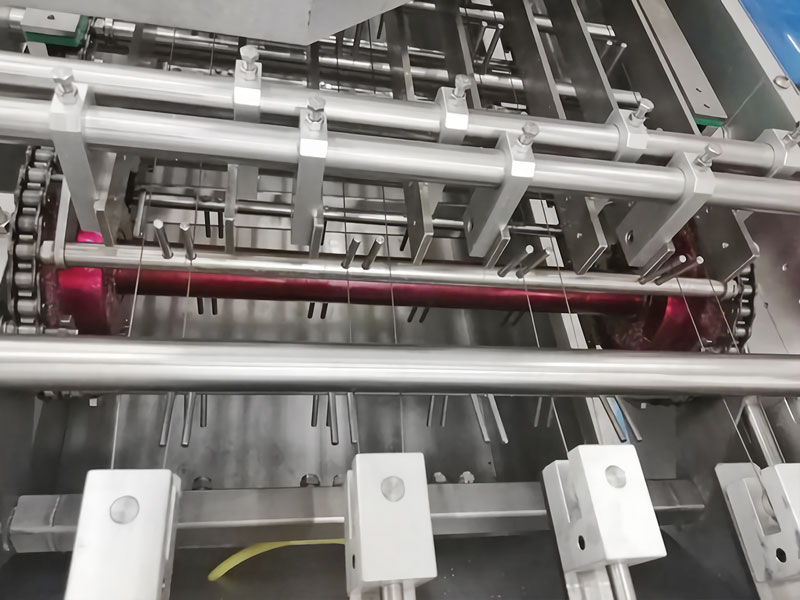

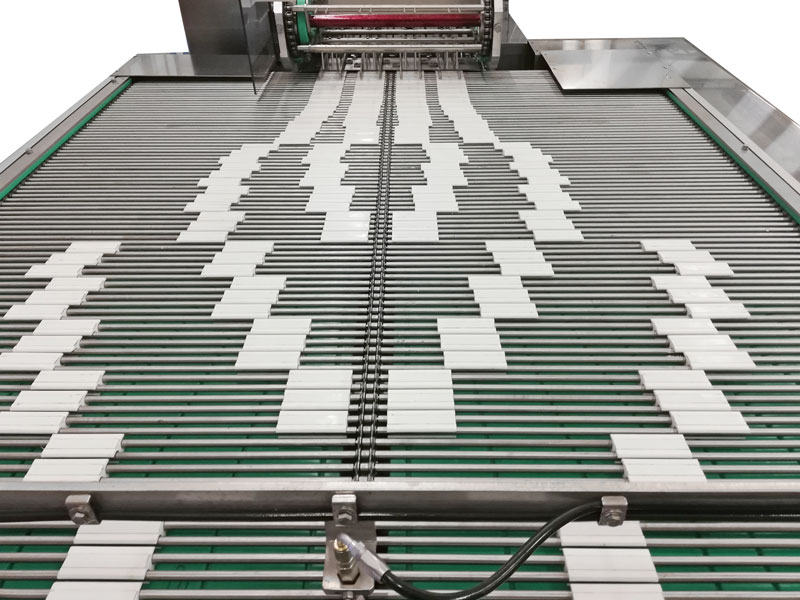

New Biscuit Transport System

Biscuit pusher pins without internal chains, only with side chains to transport the biscuits, innovative system for better cleaning, no residue accumulation on the machine, less biscuit breakage and greater performance throughout the production circuit.

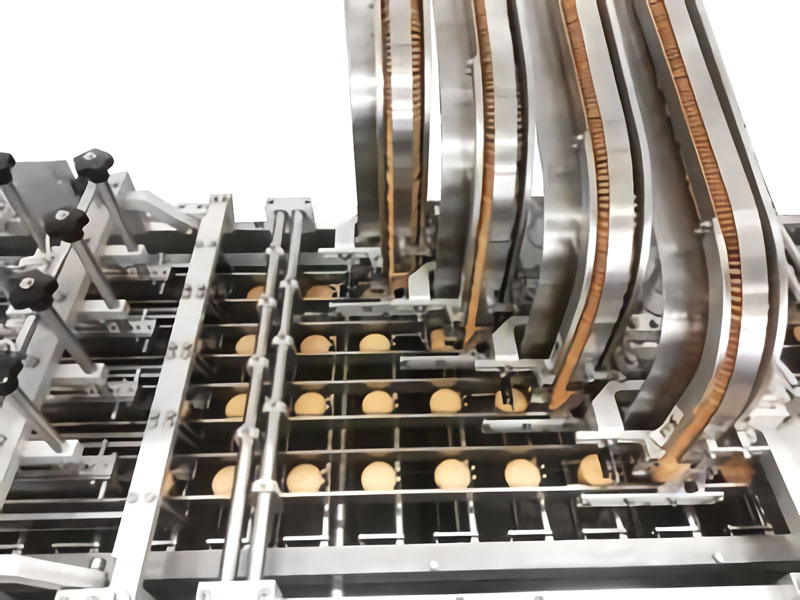

BISCUIT QUEUE MULTIPLIER IN THE OUTPUT OF SANDWICHES

FROM 4 TO 8, FROM 6 to 36… cookies according to the cooling belt

The sandwich machine queue multiplier multiplies the filling machine’s output queues by a higher number than the input queues. It is used to distribute sandwiches on a larger conveyor for packaging or cooling. Its particular high precision construction allows it to be used also during the high speed process.

ALL IN ONE TOUCH

Each solution is designed to facilitate ease of use:

user can save the working recipes for each single product and easily access via a touch-screen panel in the switchboard.

● Button panel on machine with stop, reset and emergency stop button

● Electrical control panel for sandwich filling machine, pump, stirrer and cream cochlea with inverter and speed indexed to each other

● Operator interface panel installed on Sandwich filling machine, equipped with remote control and cream pump

LASER BISCUIT LINES

TAKE YOUR PRODUCTION TO THE NEXT LEVEL

Our experience in the sector with over 500 plants commissioned, combined with the high production of machines, allows us to offer a personalized choice of solutions for each customer.

The Laser production program includes complete automatic process lines with a high productivity yield for biscuits, pastry and breads, designed and manufactured with the use of innovative technologies and excellent materials.

CHOOSE YOUR LINE

3 DIFFERENT MODELS

SM 48

• Number of rows: 6

• Biscuits dimensions: 40 ÷ 70 mm

• Production max: 4.800 biscuits / min

• Multiplier: 6×12, 6×18, 6×24, 6×36

• Optional: second cream tank

• PLC control

• Latest technology that allows a simple functioning and a quick replace of

the cream dispenser

• Manual or automatic loading system using the vibrating channels

SM 32

• Number of rows: 4

• Biscuits dimensions: 40 ÷ 70 mm

• Production max: 3.200 biscuits / min

• Multiplier: 4×8, 4×12, 4×16, 4×20

• Optional: second cream tank

• PLC control

• Latest technology that allows a simple functioning and a quick replace of

the cream dispenser

• Manual or automatic loading system using the vibrating channels

SM 16

• Number of rows: 2

• Biscuits dimensions: 40 ÷ 70 mm

• Production max: 1.600 biscuits / min

• Optional: multiplier or overlapping

• PLC control

• Latest technology that allows a simple functioning and a quick replace of

the cream dispenser

• Manual or automatic loading system using the vibrating channels

NEXT STEP

TASTE THE QUALITY

STAY IN TOUCH

The Latest News & Updates

About Us

Products

LASER S.R.L.

Via Saturno 36

37059 Santa Maria di Zevio

Verona – Italy

Ph. (+39) 045 6051428

contact@laserbiscuit.it

P.IVA 02640680233