INDUSTRIAL SPONGE CAKE LINES

SPONGE CAKE

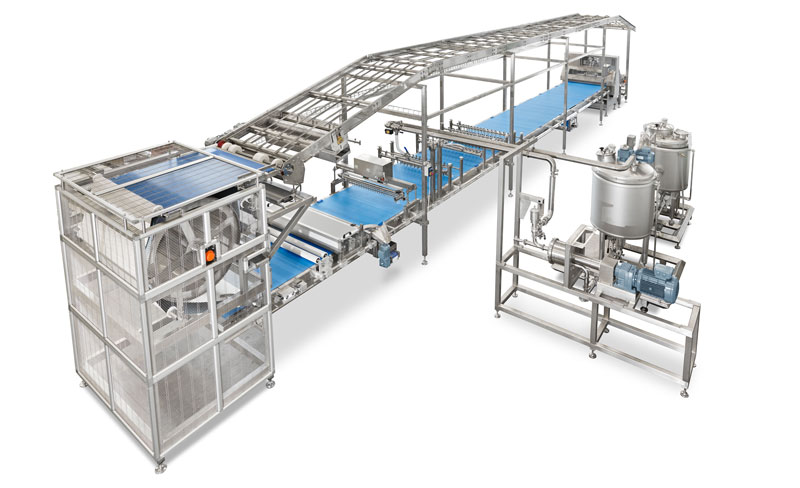

Laser realizes automatic and semiautomatic sponge cakes plants to produce layer cakes, rolls and mini rolls.

Top quality plants using the latest in technology to suit an ever changing market.

Output and reliability are of the utmost importance to us.

Our plant can be designed specifically to suit the customers production requirements.

In conclusion, the customizable lines can be complete with syrup depositor, longitudinal cutting unit, cream extruder, jam extruder, plowshares unit.

EXAMPLE OF SPONGE CAKE LINES

TURBOEMULSION MIXER

EXTRUSION

TUNNEL OVEN

COOLING CONVEYOR

WORKING TABLE

DECORATION / ENROBING

HANDLING AND PACKING

Mixers manufactured every year

THE BATTER PREPARATION IS THE FIRST PHASE OF THE PROCESS AND ONE OF THE MOST CRITICAL:

great importance is given to the homogeneity of the batter and its characteristics. How the ingredients are dosed, blended and

incorporated, producing the correct amount of gluten during mixing and developing the correct temperature is essential to have a constant and machinable product in the subsequent phases. Laser can count on different types of mixers produced internally through years of experience gained in contact with its customers all over the world.

The turboemulsion mixer is suitable to prepare liquid or cream dough. Strong structure completely made in stainless steel AISI 304, with predisposition for CIP cleaning is available in different sizes with several degrees of automation in order to sustain the sponge cake preparation process as well as the cream filling preparation. More info

different TYPE OF TUNNEL OVEN

The TUNNEL oven is the master of reference for the entire line and determines its production capacity

Proper baking and correct profiling of the parameters of each zone is the secret to obtain a constant and efficient production. Whether the oven is powered by gas, diesel or electric, which it bakes by radiation or convection, Laser has a solution for every need. Different types of baking and fuel can be combined to give an optimal and at the same time flexible result for modern industry. More info

AFTER BAKING PROCESSINGS

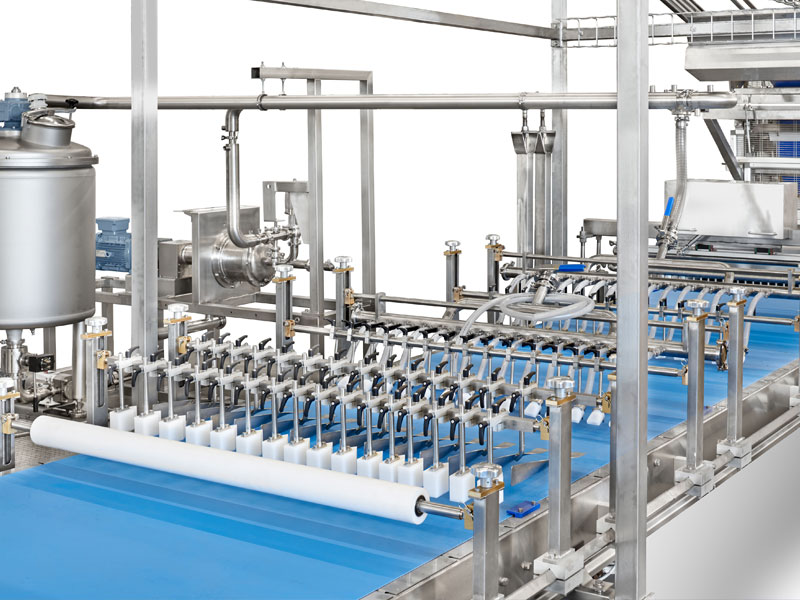

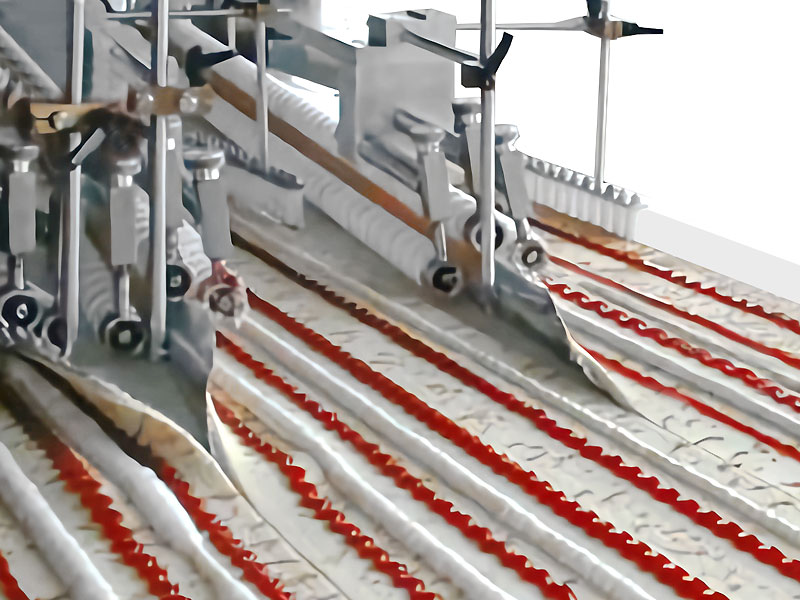

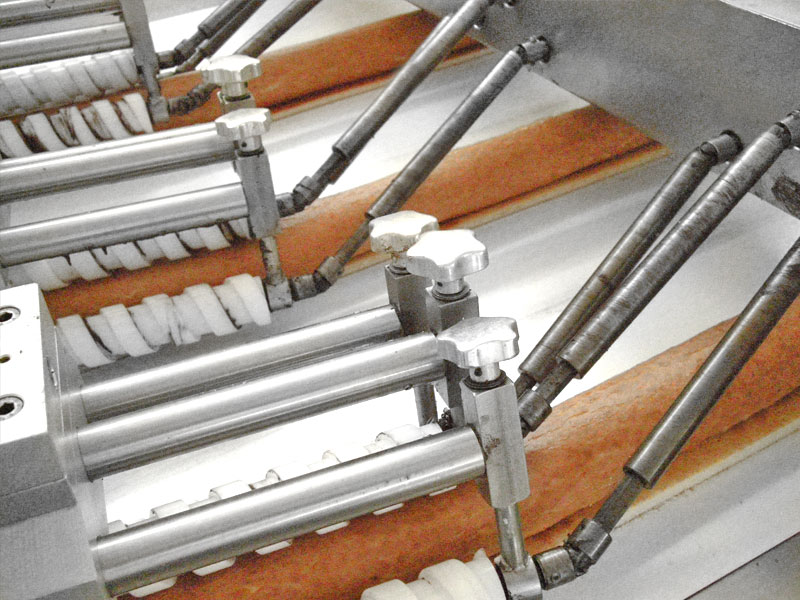

THE WORKING TABLE CAN BE EQUIPPED WITH SEVERAL TOOLS IN ORDER TO ENSURE A WIDE VARIETY OF FINISHED PRODUCTS.

After baking the sponge cake sheet is transformed in single products through different tools installed. The surface is cut in strips, wetted with syrup, then filled with different creams, jams or sprinkled products and then cut with high speed guillotines.

AND MORE solution for customizing the final product

Each production line can be customized with various accessories

to make the final product unique or make the same line more flexible and able to respond to market demands: syrup depositor, longitudinal cutting unit, cream or jam extruder, plowshares unit.

production lines installed every year

The ability to customize our lines and adapt them to the specific needs of the customeR

allows us to create a wide production of systems every year. In the sponge cake production, the extruder is responsible for the thickness of the sponge layer. Very high precision is indispensable in order to obtain constant and equal products. Sophisticated electronic control systems analyze and correct the density of the batter and control it.

LASER BISCUIT LINES

TAKE YOUR PRODUCTION TO THE NEXT LEVEL

Our experience in the sector with over 500 plants commissioned, combined with the high production of machines, allows us to offer a personalized choice of solutions for each customer.

The Laser production program includes complete automatic process lines with a high productivity yield for biscuits, pastry and breads, designed and manufactured with the use of innovative technologies and excellent materials.

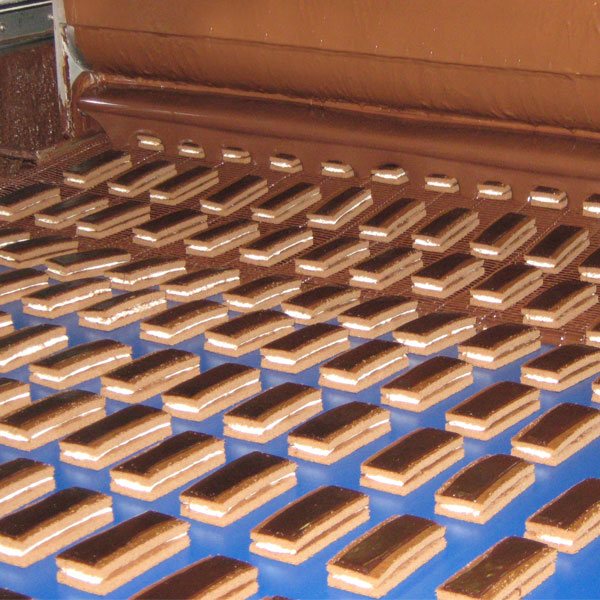

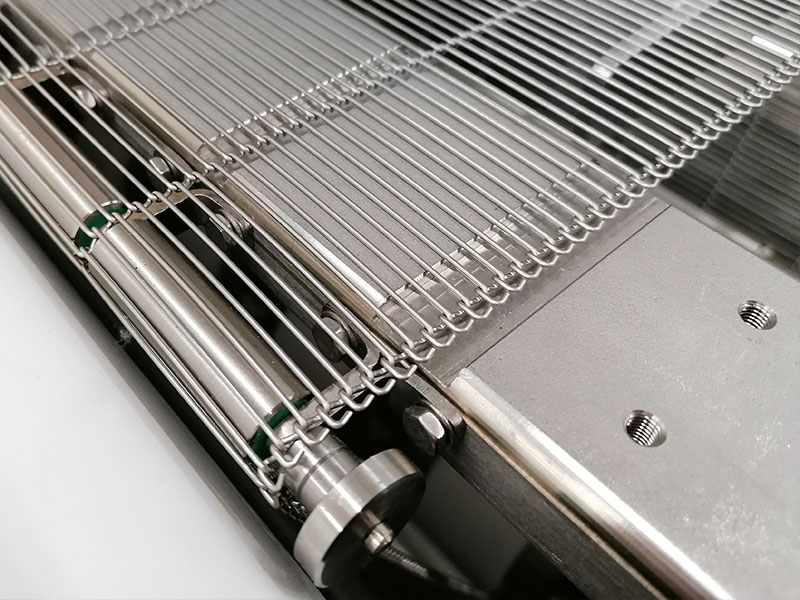

CUSTOM SOLUTIONS FOR ENROBING, COOLING, CONDITIONING AND PACKING

ONCE THE PRODUCT IS FORMED, THE SAME CAN BE ENROBED, DECORATED, COOLED AND TRANSPORTED TO THE PACKAGING SECTION,

which may be in various positions in the factory. Maintaining a constant alignment and uniform decoration and cooling are essential for obtaining a full stream of products that can be easily packed. From full width enrobers, decorator units, forced cooling tunnels up to buffer solutions for auto packaging and auto feeding anything can be supplied. The industrial design ensure a 24/7 operativity with only a minimal maintenance required.

recipes stored in our software management system

The entire system is managed completely automatically by one or more PLCs.

The software allows to manage the recipe and production parameters and also be connected to the customer’s company networks if necessary. Extensive customization and on-line assistance give the customer a support according to his production needs.

NEXT STEP

TASTE THE QUALITY

STAY IN TOUCH

The Latest News & Updates

About Us

Products

LASER S.R.L.

Via Saturno 36

37059 Santa Maria di Zevio

Verona – Italy

Ph. (+39) 045 6051428

contact@laserbiscuit.it

P.IVA 02640680233